Who We Are

Moore International are the experts in all things ballscrew, leadscrew and linear motion technology.

We are the UK's leading distributor of Swiss made Eichenberger Gewinde Ballscrews and leadscrews. Based in Poole, Dorset Moore International was established in 1997 after Managing Director Mark Moore and his brother Colin had been serving the local industry for 13 years. Since then Moore International has been committed to providing quality products and service to all customers. Because of this dedication Moore International has transformed from a small, local supplier of bearing products, to a highly-regarded manufacturer and distributor of ballscrew and leadscrew products which are sourced from the UK and Switzerland.

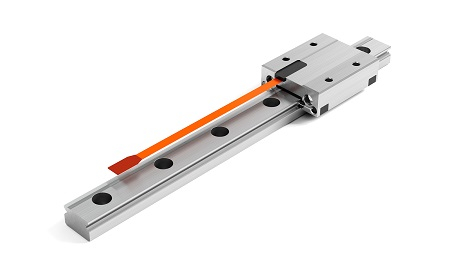

Moore International are also a key distributor of Swiss made Schneeberger Linear motion products. Schneeberger are a name synonymous with modern linear guide technology for the mechanical engineering industry. Thanks to their unyielding focus on linear motion, Schneeberger offer their customers significant technical and economical advantages that can be built into their applications. Besides Schneeberger, we also supply linear motion products by Hiwin, So if you need any linear items, please do not hesitate to contact us to discuss the right product for your application.

ISO 9001 Quality Assured

Moore International prides itself to hold ISO 9001 certification. This ensures the quality and accuracy of the products and services that it provides to industry, are kept to a high standard, at all times.

CNC Machining - CNC Turning & CNC Milling

Moore International has extensive CNC turning and milling facilities and are able to manufacture parts made to the customers specific measurements and requirements. We work with a variety of materials including aluminium, stainless steel, mild steel, tecaform and peek.

Overview of Our Products

Satellite Roller Screws

Ballscrews

Trapezoidal Leadscrews

Leadscrews (Including: Rondo, Speedy)

Linear Motion Technology (Including: Schneeberger, Hiwin & More)

Zimmer Linear Clamps (Including: Pneumatic, Hydraulic, Electric & More)